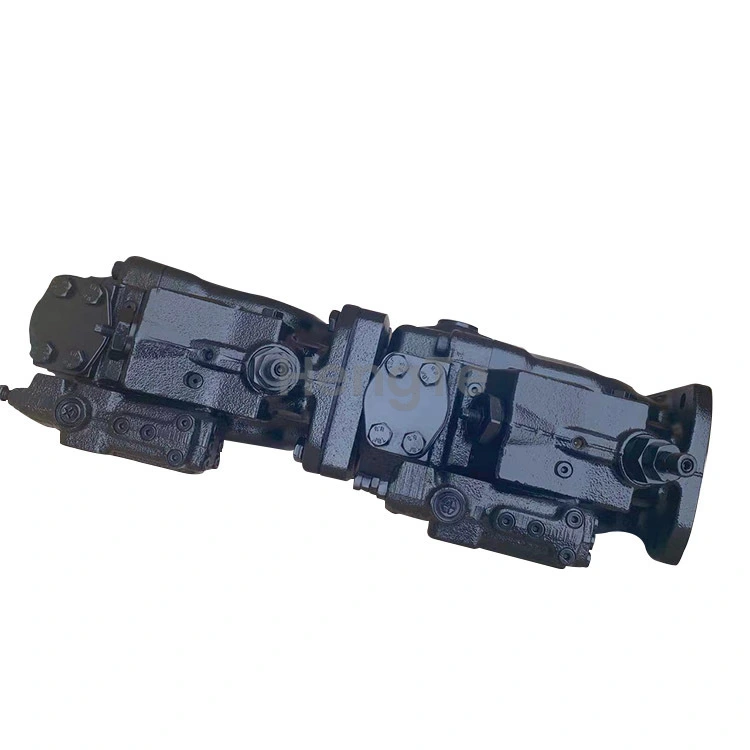

Parker Piston Pump P2060L00C1C30TA32V50C3B2P +P2060L00C1C30TA27V50T1B4P

Application: Offshore elevators and cranes, marine winches and cranes, marine diesel engines, wind turbine pitch control, pile driving equipment, railway maintenance machinery, testing rigs.

Machine Type: MiniBOOSTER

Manufacturer: PARKER

OEM: HengTe

P2060L00C1C30TA32V50C3B2P +P2060L00C1C30TA27V50T1B4P

Parker plunger pump is a hydraulic equipment commonly used in the industrial field, which can transport and drive other hydraulic systems through the pressure generated by the reciprocating motion of the plunger. This manual aims to introduce the structure, working principle, installation steps, operation methods, and common troubleshooting of the Parker plunger pump, in order to help users use and maintain the equipment correctly.

P2060L00B1B10LA20D00S1B1U

P2060L00B1B10LA20N00B1B1U

P2060L00B1B10LA20N00S1B1P

P2060L00B1B10LA20N00T1B1U

P2060L00B1B12LA20D00S1B1U

P2060L00B1B18LA18N00S1B1P

P2060L00B1B18LA20N00S1B1P

P2060L00B1B19LA20T00S1B1U

P2060L00B1B26TA25N30S1B1P

P2060L00B1B26TA25N37S1B1P

P2060L00B1B28TA25N50S1B1U

P2060L00B1B28TC20T58S1B1U

P2060L00B1B30TB25N48S1B1U

P2060L00B2B19LA20N00S1A1U

P2060L00B2B19LA20N00S1H1U

P2060L00B2B23LA10N00S1B1U

P2060L00B2B25LA20N00S1B1P

P2060L00B2B25LA20N00S1B1U

P2060L00B2B25TC20D90S1B1P

P2060L00B2B26LB20N00S1A1U

P2060L00B2B31LA35D00S1B1U

P2060L00B2B32TC30D62S1B1U

P2060L00B3B23LA15N00S1B1U

P2060L00C1C10LA15N00S1B1P

P2060L00C1C10LA15N00S1B4P

P2060L00C1C10LA20N00S1B1U

P2060L00C1C11LA20N00S1B4P

P2060L00C1C12LA18N00B1B1P

P2060L00C1C15LA20N00S1B1U

P2060L00C1C18LA20N00C1A1U

P2060L00C1C18LA20N00S1A4U

P2060L00C1C18PA00N00T1A1P

P2060L00C1C19PA00N00B1B1U

P2060L00C1C20LA20N00A1B1P

P2060L00C1C20LA20N00C3B3P

P2060L00C1C20LA20N00S1B1U

P2060L00C1C21LA18N00S1B1P

P2060L00C1C21LA18N00S1B1U

P2060L00C1C21LA18T00S1B1P

P2060L00C1C21LA20N00S1B1P

PRODUCT DISPLAY

FEATURES

Parker plunger pump is a hydraulic equipment commonly used in the industrial field, which can transport and drive other hydraulic systems through the pressure generated by the reciprocating motion of the plunger.

Parker plunger pump is a hydraulic equipment commonly used in the industrial field, which can transport and drive other hydraulic systems through the pressure generated by the reciprocating motion of the plunger. This manual aims to introduce the structure, working principle, installation steps, operation methods, and common troubleshooting of the Parker plunger pump, in order to help users use and maintain the equipment correctly.

Applied to:

Stamping machines/material forming machines, scrap scissors, offshore elevators and cranes, marine winches and cranes, marine diesel engines, wind turbine pitch control, pile driving equipment, railway maintenance machinery, testing rigs and HPU/integrated systems.

STRUCTURE AND WORKING PRINCIPLE

Parker plunger pump mainly consists of pump body, plunger, inlet and outlet valves, etc. Its working principle is to drive the pump shaft to rotate through an electric motor or engine, causing the plunger to move back and forth within the pump body, thereby generating pressure to transport liquid. The specific working principle is as follows:

Water inlet stage: When the plunger moves backwards, the inlet valve opens, forming a negative pressure area to suck in liquid; Push oil stage: When the plunger moves forward, the inlet valve closes and the outlet valve opens, pushing the liquid to the external system.

Return stage: When the plunger moves backwards again, the outlet valve closes and the return valve opens, returning the liquid back into the pump body.

Installation steps

Correct installation is crucial for the normal operation of the Parker DuPont pump. The following is a detailed description of the installation steps:

1. Ensure that the installation foundation is flat and firm, and meets the requirements of the equipment;

2. Fix the pump body on the foundation, ensuring that the inlet and outlet correspond to the pipeline:

3. Install auxiliary equipment such as fuel tanks and filters as needed;

4. Connect the motor or engine to the pump shaft to ensure that the transmission part is correct;

5. Check whether all connections are tightened and reliable, and eliminate oil leakage and looseness.

Operation method

1. Pre start inspection: Check whether the power or fuel supply is normal, whether the liquid level in the oil tank is sufficient, and whether there are foreign objects in the pump body;

2. Starting equipment: Press the start button or pull wire on the operation panel to start the equipment;

3. Monitoring pressure: Monitor the system pressure through a pressure gauge or sensor to ensure it is within the normal range;

4. Operation control valve: Adjust the flow and pressure through the control valve according to actual needs;

5. Stop equipment: The stop button or pull wire on the operation panel can stop the equipment from working; 6. Close the valve: After stopping the equipment, close the inlet and outlet valves to avoid liquid backflow.

Good after-sales Service: We will solve your problems about goods, and including online support.

Original packing, neutral packing or customized packing

100% product quality protection

100% on-time shipment protection

Quick response within 24 hours

PRODUCT PARAMETERS

|

Condition |

New |

|

Parts number |

P2060L00C1C30TA32V50C3B2P +P2060L00C1C30TA27V50T1B4P |

|

Place of Origin |

Guangdong, China |

|

Original |

PARKER |

|

Application |

Offshore elevators and cranes, marine winches and cranes, marine diesel engines, wind turbine pitch control, pile driving equipment, railway maintenance machinery, testing rigs. |

|

Quality |

High Guarantee |

|

Package |

Standard Export Package |

SIMILAR REPLACEMENT MODELS INCLUDE

The commonly used models of Parker P2 series plunger pumps are:

P2060L00C1C30TA32V50C3B2P+

P2060L00C1C30TA27V50 American Parkson Piston Pump

P2060L00C1C30TA32V50C3B2P+

P2060L00C1C30TA27V50T1B4P

P2105R00C3C24LA20N00S1A1P,

P1140PS01SRM5AC00S000PB00,

P2105R00C5C25PA00N00A1A2U,

P2105R00C1C32LA20N00C3B1P,

P2105R00C1C25PA00N00B2A1U,

P2105R00C5C14PB00N00S1A1U,

P2075R00C1C10LA20N00S1B1U,

Parker dual piston pump/Parker combination

variable pump

P2145R00D1D25TB20N55D3B2P+P2145

Parker dual plunger pump P3145R90D1D28LA23N00B1B1B1E+P3145

Parker dual plunger pump P2145R00D1D25TB20N55D3B2P+P2145

Sany Crane Parker Dual Piston Pump P2060L00C1C30TA32N50C3B2P+P2060

P2105R00D1D25TB20N55T1B1P

P2105R00D1D25TB20N55T1B2

P2145R00D1D25TB20N55T1B1P

P2145R00D1D25TB20N55T1B2P

P2145R00D1D25TB20N55D3B4P

P3145R00D1D25TB20N55T1B1P

P3145R00D1D25TB20N55T1B2P

Parker combination variable pump:

P2105+P2105

P2145+P2145

P2145+P2105

P3145+P3145

PV270+PV080

PV270+092,

Roadheader Parker P2145 Series P2145 Hydraulic Plunger Variable Pump

Parker plunger pump P2 series: P2060, P2075, P2105, P2145

PARKER Plunger Pump P3 Series: P3075, P3105, P3145

The main models of Parker dual plunger pump products are as follows:

Double plunger pump P2145R00D1D25TB20N55D3B2P+P214

Double plunger pump P2105R00D1C20LB20N00C3B2P+P210

P2105R00C3C24LA20N00S1A1P,

P1140PS01SRM5AC00S000PB00,

P2105R00C5C25PA00N00A1A2U,

P2105R00C1C32LA20N00C3B1P,

P2105R00C1C25PA00N00B2A1U,

P2105R00C5C14PB00N00S1A1U,

P2075R00C1C10LA20N00S1B1U,

P2105L00C1C25PA00N00B1A1U,

P2105R00C1C22LA20N00A1B1P

(P2105R00C1C22LA20N00A1B1P,

P2075L00C1C28LA35V00S1B1U,

P1140PS02SLM5AL00S0000000,

P2105R00C1C21RA20N00S1A1U,

P2105R00C5C24TA20N53S1A1U,

P2105R00C1C21LB20N00S1A1P,

P2105R00C5C20PA00N00S1A1U,

P2105R00C5C22PA00N00S1A1P,

P1140PS02SRM5AC00T00B0000,

P2105R00C1C29LA27V00B1A1P,

P2105R00C5C20PB00N00S1A1U,

P2105L00C1C17LB21N00S1A1U,

P2105R00C5C17TD20N80S1A1P,

P2105R00C6C30TD20N60C3A1P,

P2105L00C6C32LB20D00C3B2P,

P1140PS01SLM5AL10S100PB00,

P2105L00C1C28RA24N00S1A1P,

P2060R75B2B25TA20N20S1B1U-12,

P2105R00C1C20LA20N00A1B1P,

P2105L00C1C32LA20N00S1A1U,

P2105R00C5C25PA00V00C3A1U,

P2105L00C5C07PB00N00B1A2P,

P2075R00C1C31TB20N40S1B1P-12,

P2105L00C1C17LB20N00C3A1P,

P2105R00D1C26LA20N00S1B1P,

P2105L00C1C10LA20N00S1A1U,

P2105L00C1C13LA28N00C3A2U,

P2105R73C5C10PA00N00B1A1U,

P1140PS01SRM5AL00T00C0000,

P2075L00C1C30LA30N00B1B1U,

P2105R00C1C10RA20N00C3A1U,

P2105R00C1C25LA20N00S1B1U-11)

P2105R00C5C12PA00N00S1A1U,

P2105L00C6C19LA20N00C3A1U,

P2105R00C1C32LA20N00S1B1U,

P2105R00C6C25PA00N00C3A1U,

P2105R00C1C29LA27V00S1A1P,

P2105R00C1C30LA20N00B1A1U,

P2105L00C1C21LA20N00C3A1P,

P2105R00C1C10RA20N00C3A1U,

P2105R00C1C25LA20N00S1B1U-11)

P2105R00C5C12PA00N00S1A1U,

P2105L00C6C19LA20N00C3A1U,

P2105R00C1C32LA20N00S1B1U,

P2105R00C6C25PA00N00C3A1U,

P2105R00C1C29LA27V00S1A1P,

P2105R00C1C30LA20N00B1A1U,

P2105L00C1C21LA20N00C3A1P,

P2105R00C1C25PA00N00S1A1U,

P2105R00C1C10PA00N00C1A1U,

P2105R00C1C24PA00N00S1A1U,

P2105R00C1C19LA20N00S1A1U,

P2105R00C1C25LB20N00S1A1P,

P2105R00C1C30LA25N00S1B1U-11,

P2105R00D1C18LB20N00C3B2P,

P2105R00C6C17LA20N00B1A1P,

P2145R00D3D35TA20N29B1B1U,

P2105R92C5C17PA00N00A1A1U,

P2105R00C5C19LA20N00S1A1U,

P2105R00C6C25PA00N00C3A1U,

P2105R00C5C31PA00V00S1A1P,

P2105R00C5C17LA17N00S1A1P,

P2105R90C1C32TC20T76C3A1U,

P2105R00C1C20TC20N55A1A1U,

P1140PS02SRM5AC00T00A0000,

P2105R00C5C31TD10V50S1A1P,

P2075R00C1C22LA20N00T1B1P,

P2105R00C2C28TD20N60C3B1U,

P2105R00C5C25PA00N00S1B1U,

P2105R00C1C12PA00N00S1B1P,

P2105R85C6C22LA20N00S1A1U,

P2105L00C1C28RA24N00S1A1P,

P2105R00C5C30TA20N40A1A1U,